Pipe Launder

Pipe Launder Slope Determination

Determination of slope required to pass a given fluid velocity through a pipe launder of a given geometry

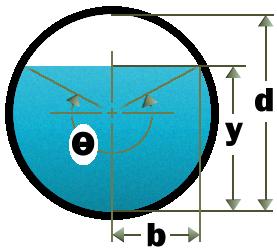

and a half-top (b) dimension of 0.40 metres, 15.81"

Hydraulic radius (Rh) of this geometry is 0.265 metres; 10.4"

Flow (Q) that will pass this launder is 6831.0 m3/h, 30076.9 usgpm

Slope of this launder to achieve desired velocity is 1.6%, 0.91°.

Calculation Backup:

Slope = ( n × V × Rh(-2/3) ) 2

where Slope is height/length, V is m/s and Rh is in metres.

The Manning Equation used here is a commonly civil engineering formula for culverts and canal design. More on Manning equation and its parameters here.

Disclaimer: USE AT YOUR OWN RISK.

Neither the author nor the web host will accept any responsibility for loss or damage caused by use of this program. The program has not been tested under stringent conditions that allow it to be considered robust enough for Engineering use. People using this program must themselves accept responsibility to confirm that results are correct and applicable to the application being calculated.